The pharmaceutical industry is highly regulated, and ensuring the quality and integrity of medication is of utmost importance. Vials, often made from glass or plastics, play an important role in storing medication in liquid form. One critical aspect of vial inspection is the liquid level, which ensures accurate dosing. Traditionally, this task has been performed manually. The advancements in deep learning and computer vision have paved the way for automated inspection in many manufacturing sectors, including pharma, and inspecting the liquid level of vials is one example. This brief article explores the potential of PEKAT VISION in enhancing vial quality control and highlights the benefits it brings to the pharmaceutical manufacturing process.

PEKAT VISION is based on proprietary deep-learning algorithms and neural networks, a subset of artificial intelligence that has revolutionized the field of computer vision by enabling machines to automatically learn and recognize complex patterns in images. Leveraging these algorithms, PEKAT VISION can analyze images of vials and accurately detect the liquid level within them.

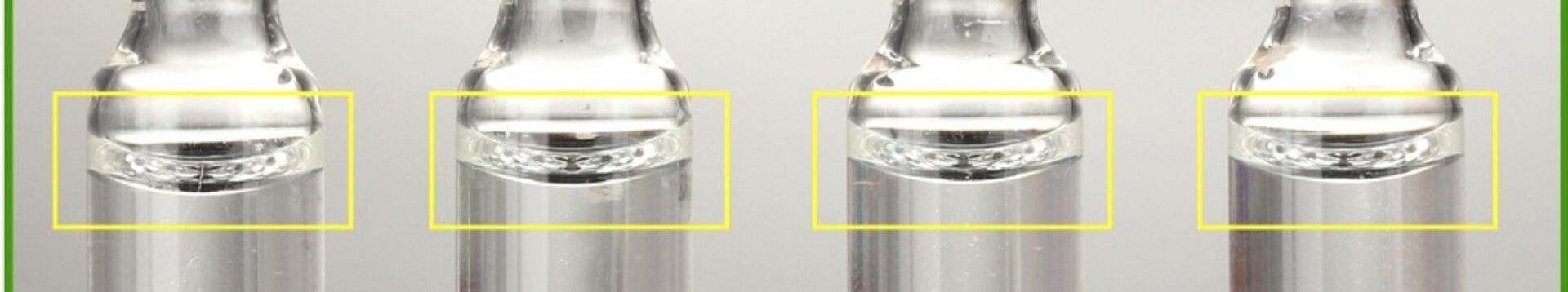

To develop a robust model for liquid level inspection in PEKAT VISION, a set of vial images is required. These images consist of vials with varying liquid levels, encompassing both acceptable and defective examples. Because the vials appear always in the same position in the images, the Classifier module is sufficient for this task. After selecting the module, these images are labeled in PEKAT VISION’s user-friendly interface by a trained employee and are assigned appropriate classes. The deep learning model learns from the labeled data to identify patterns and features associated with different liquid levels. By training the model on diverse images, it learns to differentiate between acceptable and defective liquid levels with high accuracy.

Once trained, PEKAT VISION can be integrated into the pharmaceutical manufacturing process. In order to speed up the integration process, PEKAT VISION offers a number of predefined output rules. Once fully integrated, as the vials move along the production line, they pass through a camera system that captures images. Using the trained model, these images are then analyzed in real-time in PEKAT VISION, identifying any vials with incorrect liquid levels. Defective vials can be flagged for further inspection or removal, ensuring that only vials with the correct fluid level reach the market.

Together with the liquid level inspection, additional checks can be performed, such as detecting the presence of unwanted particles or sediments, as well as cracks and other defects on the vial bodies that could compromise the contents of the vials. In such cases, it is necessary to inspect each vial using multiple cameras from different angles simultaneously and utilize multiple PEKAT VISION modules at the same time.

Implementing PEKAT VISION’s deep-learning based visual inspection software in these cases offers numerous benefits. The benefits are however not limited to pharmaceutical manufacturing only and include, among others, increased efficiency and cost savings, improved quality control, and enhanced product safety

If you wonder whether PEKAT VISION can improve your quality control too, please, send us an email, request a free demo, or a free feasibility study.