Vizuální kontrola pomocí umělé inteligence se stává klíčovou součástí kontroly kvality nejen v elektronickém průmyslu. Schopnost Umělé inteligence detekovat vady s vysokou přesností a rychlostí z ní učinila atraktivní řešení pro výrobce, kteří chtějí zlepšit kvalitu svých výrobků a snížit náklady na manuální kontrolu.

PEKAT VISION nabízí vizuální kontrolu elektronických součástek a desek plošných spojů (PCB) založenou na hloubkovém učení a neuronových sítích. Naše technologie spolehlivě identifikuje vady, jako jsou chybějící součástky, špatně osazené díly, vady pájení i mnoho dalších, včetně anomálií, které lze jen těžko dopředu předvídat.

Mezi výhody technologie PEKAT VISION patří vysoká přesnost, rychlost, nižší náklady a vyšší konzistence kontroly kvality. PEKAT VISION se snadno používá, nastavuje a udržuje. Podívejte se na příklady níže nebo požádejte o demo verzi nebo studii proveditelnosti a přesvědčte se o výhodách našeho softwaru na vlastní oči.

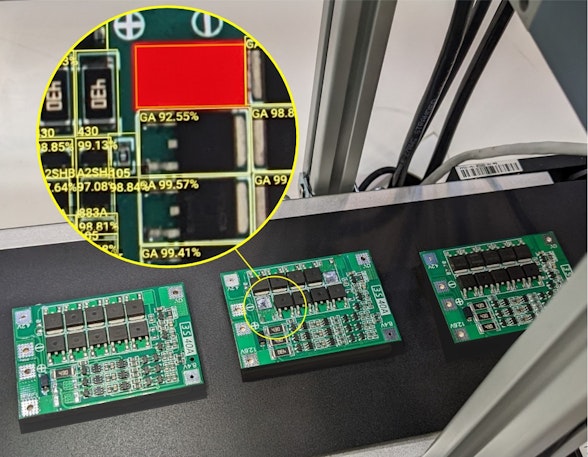

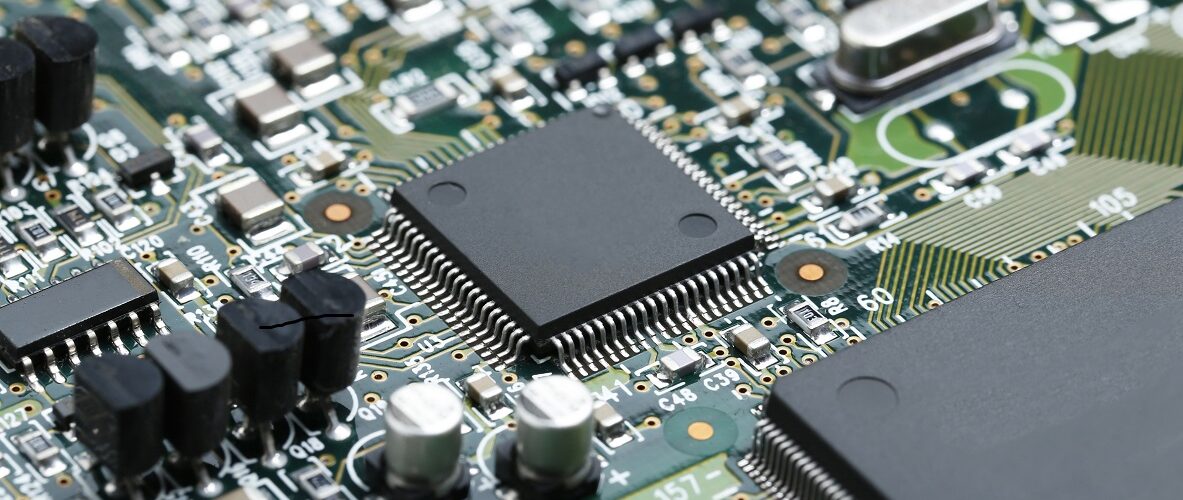

Kontrola desek plošných spojů

Moduly Detektoru a Klasifikátoru jsou ideální pro ověřování přítomnosti a stavu (OK/ NOK) jednotlivých komponent desek plošných spojů. Na obrázku výše je kontrolováno více než padesát jednotlivých součástek.

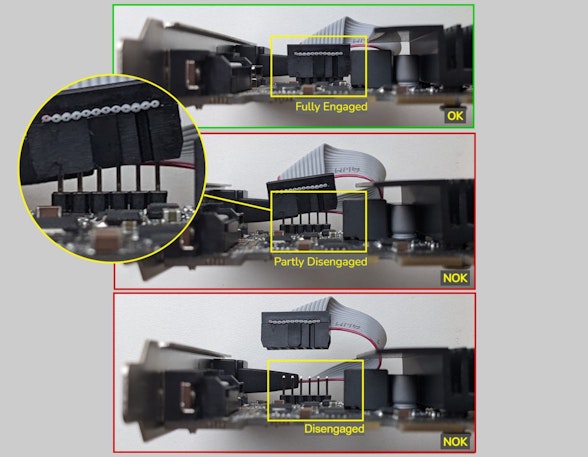

Ověření správného zapojení konektorů

Na obrázcích výše je kontrolováno správné zapojení konektorů. Jelikož jsou součásti na snímcích vždy ve stejné poloze, stačí ke kontrole modul Klasifikátor.

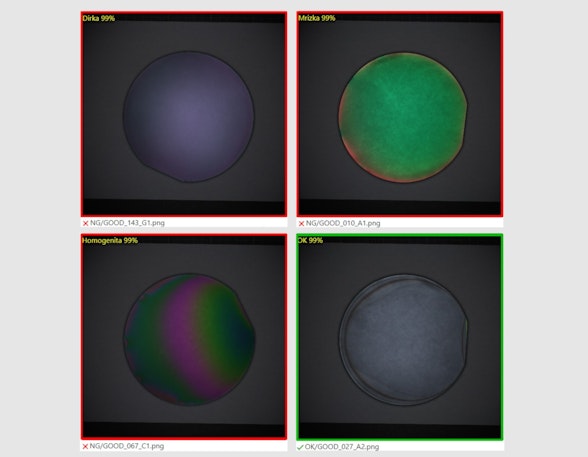

Klasifikace waferů (substrátových desek)

Moduly Detektor a Klasifikátor mohou být použity také ke kontrole a klasifikaci substrátových desek.

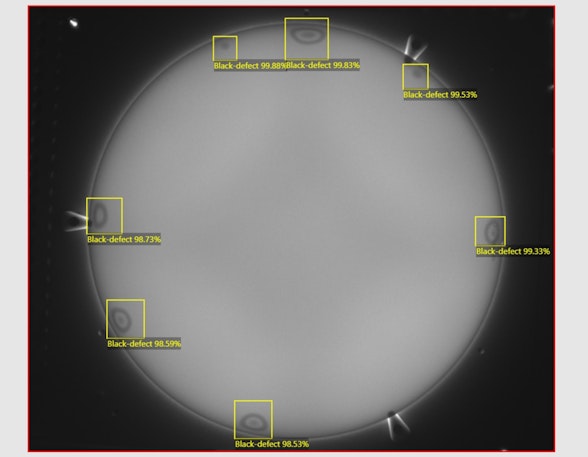

Kontrola vnitřních vad waferů

Vnitřní vady substrátových desek vyobrazených výše jsou identifikovány moduly PEKAT Detektor a Klasifikátor.

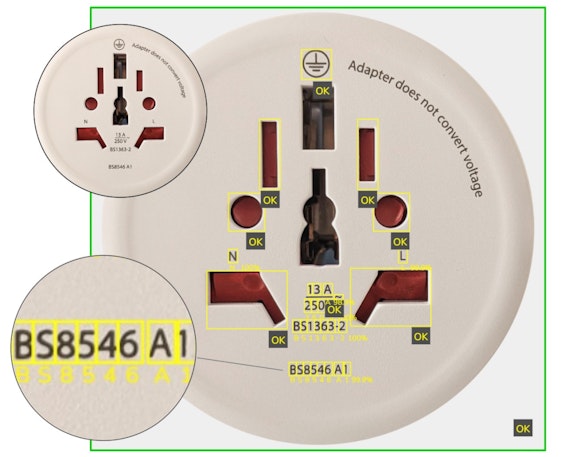

Ověření bezpečnostních prvků

Na obrázku výše jsou moduly Detektor a OCR použity společně k ověření, zda jsou přítomny všechny bezpečnostní prvky zásuvkového adaptéru, včetně požadovaného označení a ochranných plastových krytů.

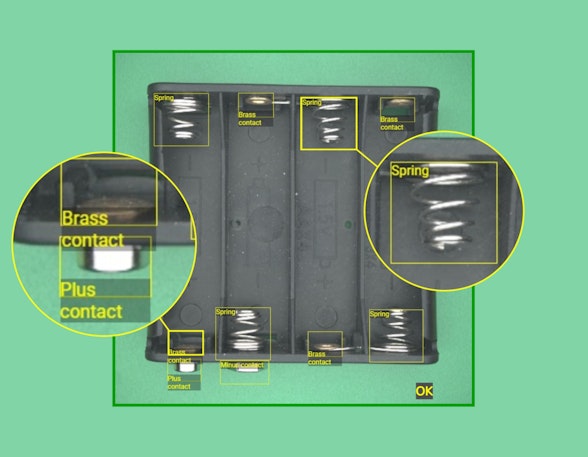

Kontrola přítomnosti komponent

Tento příklad demonstruje kontrolu přítomnosti součásti. Všechny součásti, včetně mosazného kontaktu, pružiny a minusových a plusových kontaktů, jsou identifikovány a potvrzeny.

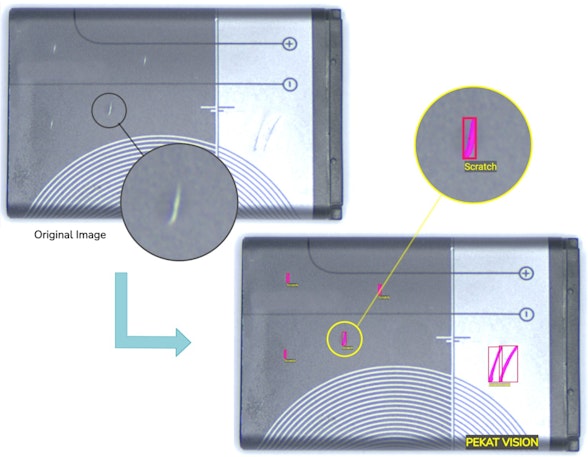

Kontrola povrchu baterie

Modul PEKAT VISION Detektor povrchu detekuje a klasifikuje různé typy povrchových vad, které se mohou vyskytnout během výrobního procesu baterií, včetně škrábanců, promáčklin a zbytků lepidla. Přestože na demonstraci je zde použita baterie do mobilního telefonu, obdobná kontrola, včetně přítomnosti cizích těles, se provádí i u baterií do elektroaut.

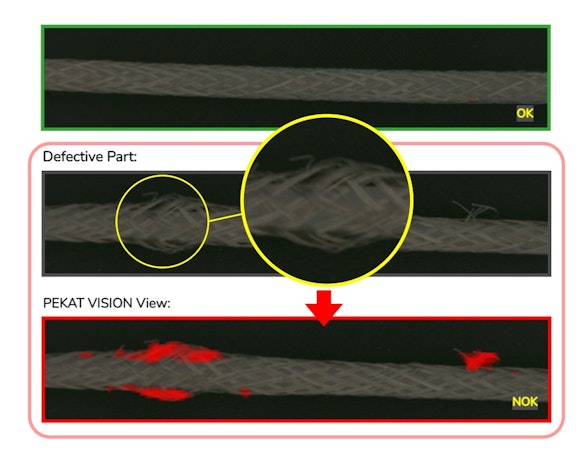

Detekce anomálií stíněného kabelu

Pomocí modulu Detektoru anomálií se kontroluje neporušenost opleteného stínění kabelu. Závady jsou snadno identifikovány a zvýrazněny pomocí heatmapy. Modul je trénován výhradně na snímcích bez závad.

Why PEKAT VISION

And more! Ask for a free feasibility study for your specific case. Our software is highly versatile and can be customized to suit nearly any intended application.