PEKAT VISION offers numerous advantages over traditional methods of quality control in the plastics and rubber manufacturing sector, including greater accuracy, consistency, and speed. This translates into higher efficiency, lower costs, and better product quality.

The outcome of injection molding, for example, is affected by a number of factors, including the raw material, mold quality, temperature, pressure, speed etc., resulting in the occurrence of defects. These defects may include various types of stains, burrs, inclusions, voids or cracks.

PEKAT VISION consists of several modules able to identify such defects, detect missing parts and read an verify any sign and symbol. It can even detect defects, such as stains, micro voids, cracks, or inclusions, that are difficult to identify manually or by a rule-based system, as they are too small or hard to notice. Furthermore, for cases when the form of the defect is difficult to anticipate, PEKAT VISION offers the Anomaly Detector module, requiring only defect-free images for training. Below you can view a few examples.

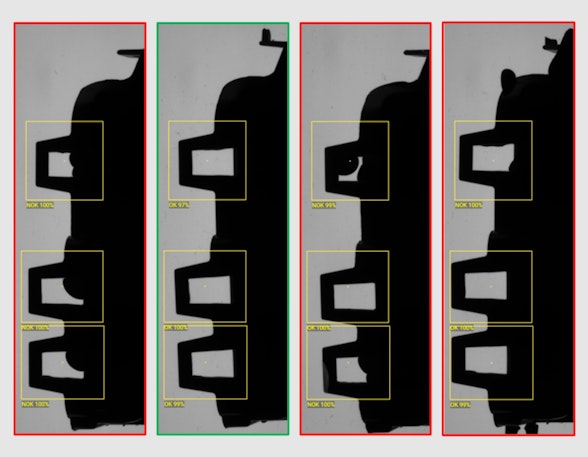

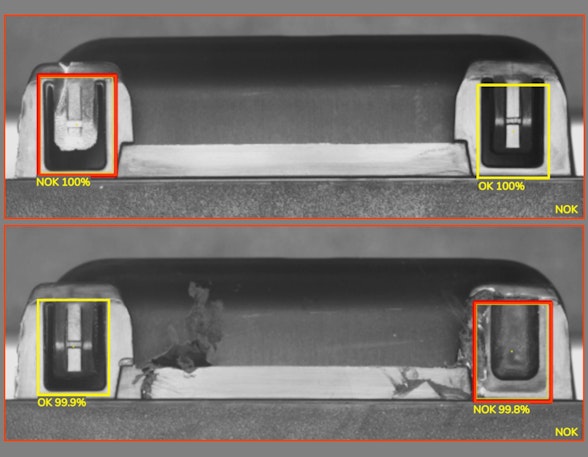

Molded Plastics – Clip Inspection

The three clips where defects may occur are inspected using PEKAT VISION Detector and Classifier modules. Backlight helps identify the defects

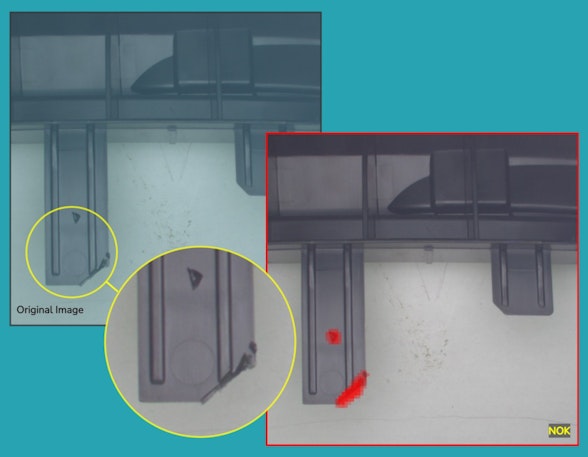

Detection of Unknown Defects

Even if the shape, size, location, or kind of the defect is hard to predict in advance, the defects can still be easily detected using the Anomaly Detection module

Final Product Inspection

Final product quality inspection with PEKAT VISION, before product is shipped, ensures that only flawless products get into the customers‘ hands, important particularly for high-end and luxury brands. The Detector module has been used in this case

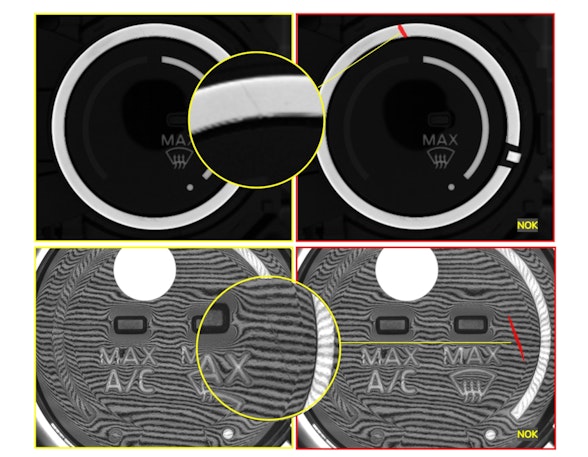

Scratch Detection

Before assembly, these volume control knobs are inspected with PEKAT VISION Surface Detector module for surface flaws, such as scratches. Various techniques, such as line pattern projection as at the bottom image, help in identifying these defects

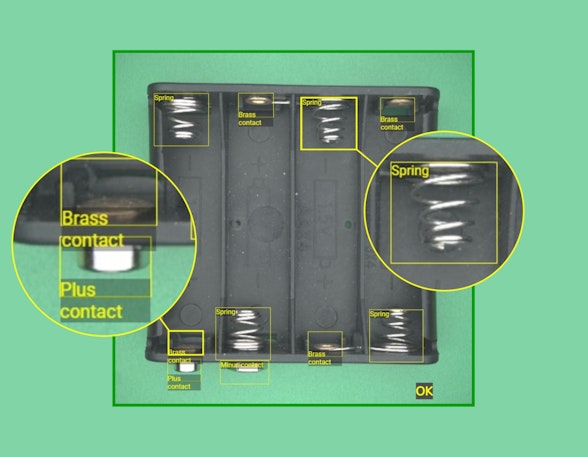

Assembly Verification

Completeness Inspection of assembled plastic parts can be easily done with PEKAT VISION Detector and Classifier modules. If any component is missing, the sample will be evaluated as NOK

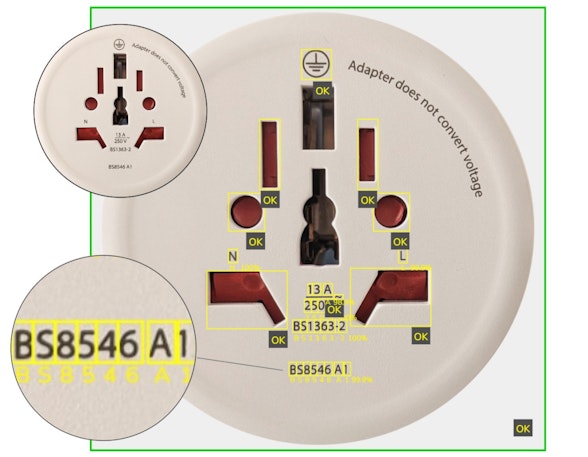

OCR and Safety Features Verification

The various modules of PEKAT VISION can be combined. In this case, the OCR module and text verification module is combined with the Object Detector module, verifying that all safety parts and symbols are present

Plastic Parts Inspection

Object Detector is used in the above example to detect faulty clips on molded plastics

Why PEKAT VISION

And more! Ask for a free feasibility study for your specific case. Our software is highly versatile and can be customized to suit nearly any intended application.