基于人工智能的视觉检测已成为汽车制造过程中不可或缺的一部分。几年前,这一技术曾为汽车制造商带来竞争优势,如今已成为必不可少的制造要素。PEKAT VISION 从一开始就与领先的制造商密切合作。

从汽车零部件供应商的装运前检验到装配厂的装配前检验,PEKAT VISION 在防止制造过程后期出现昂贵的返工方面发挥着至关重要的作用。其应用可延伸至车辆运往展厅之前的最终检查,从而减少浪费、提高产品质量及生产率,满足严格的车辆安全标准。

PEKAT VISION 可以高效处理任何需要目视检查的汽车部件,包括缺陷检测、完整性检查、产品分类、OCR(光学字符识别)或字符验证。

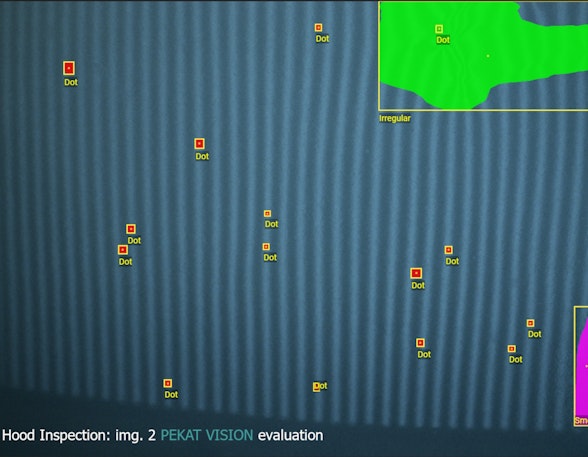

车身面板检查

PEKAT VISION可精准识别各类车身覆盖件的外观缺陷,如凹坑、漆面皱褶、清漆瑕疵及划痕等。如检测示意图所示,通过表面投射结构光栅,配合面阵扫描相机与表面检测模块,可实现微小缺陷的清晰成像与识别。

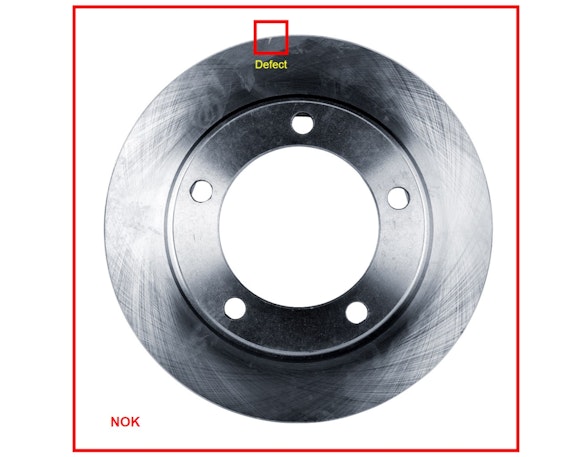

动力总成及底盘检测

针对动力传动系统及底盘部件,PEKAT VISION可对包括制动盘等安全关键件进行视觉检测。系统可高效识别裂纹等高危缺陷,避免因部件失效引发的制动过热、异常噪音及加速磨损等安全隐患。

内饰部件检查

通过多模块协同工作,PEKAT VISION可对塑料内饰板、座椅面料等内饰部件进行缺陷检测及装配验证,确保零部件的外观质量与装配符合性。

其他汽车零部件检测

PEKAT VISION可覆盖各类汽车零部件的外观与功能检测。如示例所示,目标检测器模块可识别车钥匙表面的细微划痕及功能性缺陷。

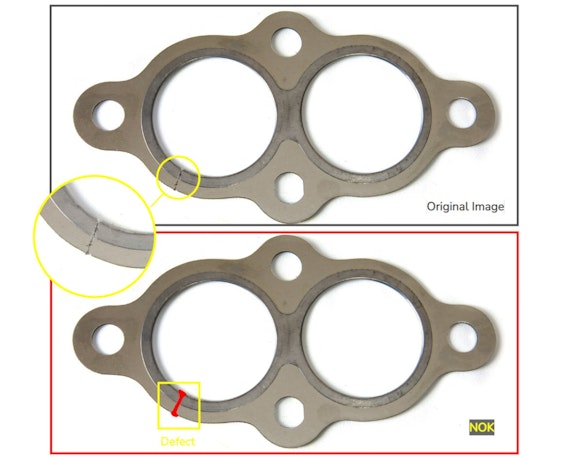

预装配检测

实施组件预检可显著降低返工成本。如表面检测模块应用案例所示,多模块协同检测方案可有效提升预装配检测效率。

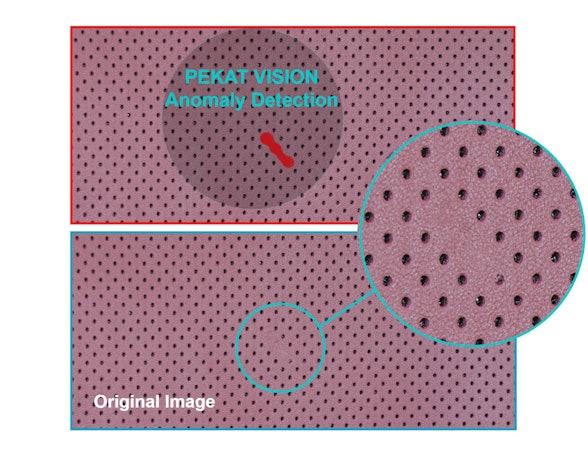

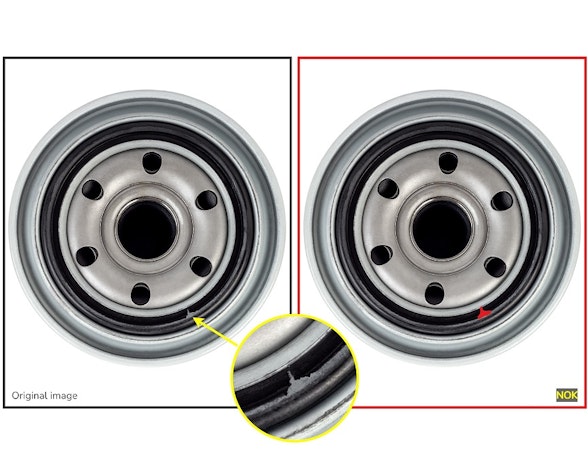

机油滤清器密封检查

采用异常检测模块对滤清器密封件进行检测,通过无缺陷样本训练模型,可精准识别密封缺失或结构异常,避免发动机漏油风险。

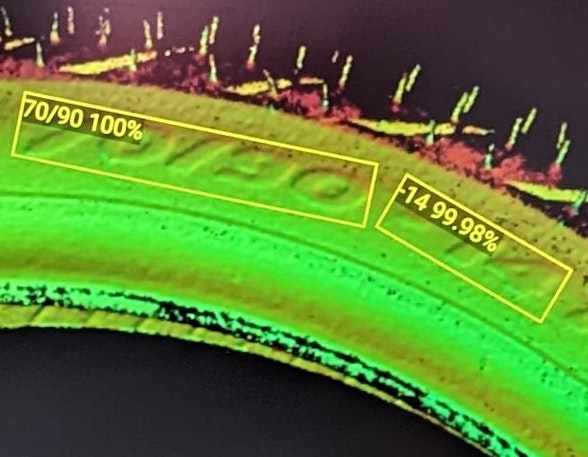

OCR/ OCV

基于深度学习的OCR(光学字符识别)与OCV(光学字符验证)模块,可读取冲压件编码、序列号、厂商标识及批次信息,实现零部件追溯与装配防错。

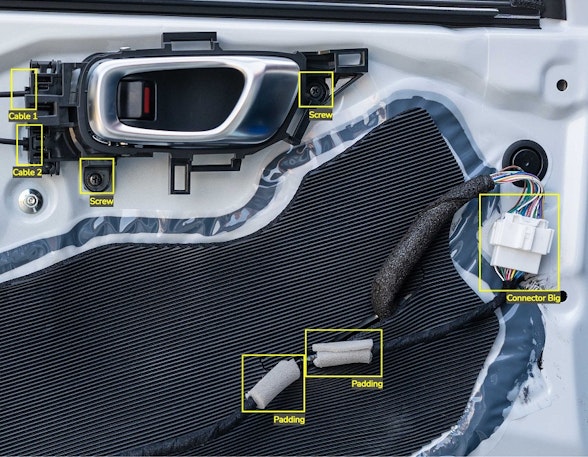

预装配验证

在车门模块组装环节,目标检测器模块通过对比标准件图像(OK)与缺件图像(NOK),验证组件装配完整性。

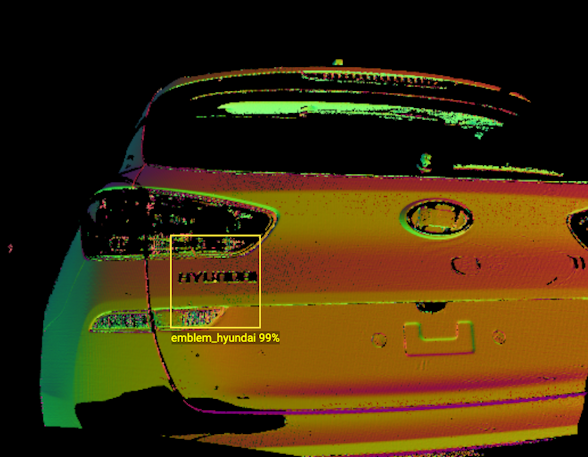

终检验证

终检环节通过3D扫描设备与PEKAT VISION协同,确认后视镜、车灯、门把手等外饰件的装配正确性。

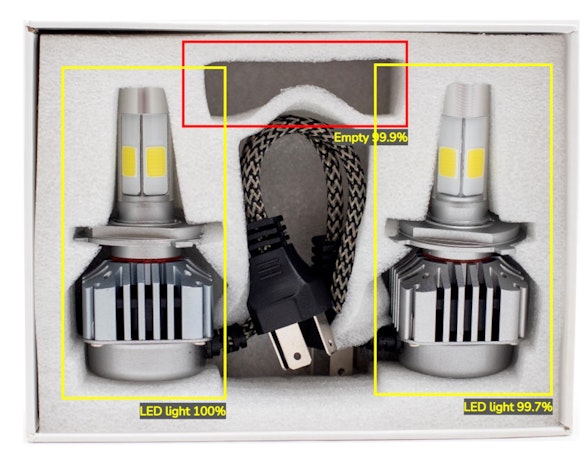

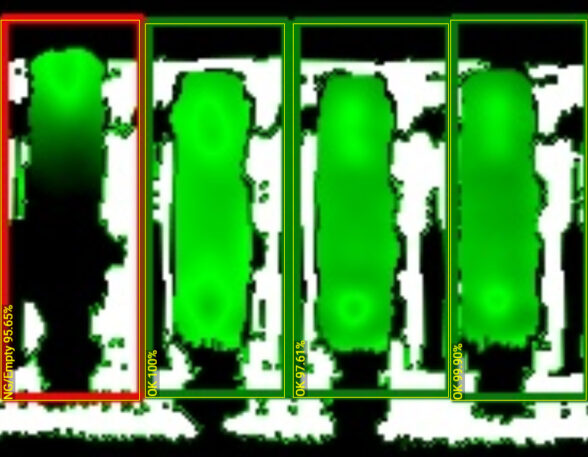

备件完整性检查

PEKAT VISION可对包装件及总成件进行完整性验证,确保所有规定组件均已正确装配。

保险丝盒3D检测

结合OCR与分类器模块,PEKAT VISON可验证保险丝盒内每个保险丝的规格型号及插装状态。可通过我们的技术博客了解更多内容。

为何选择 PEKAT VISION

还有更多功能!欢迎就您的具体案例咨询免费可行性研究。本软件具有高度通用性,可根据各类应用场景进行定制化解决方案适配。