If you missed our workshop in Brno this week or want a quick recap of the demos we presented, this post is for you. Together with our partners Smart Vision Lights and Spinbotics, we demonstrated use cases combining AI-based visual inspection, robotics, and industrial automation. The event featured insightful presentations alongside hands-on, live demonstrations. Below is an overview of the main demos from the day:

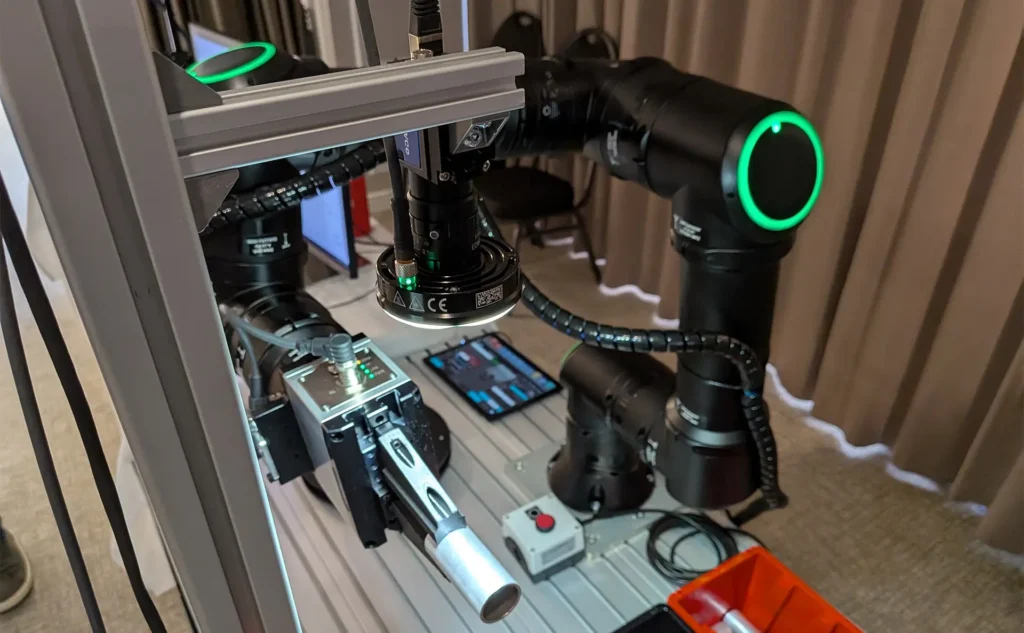

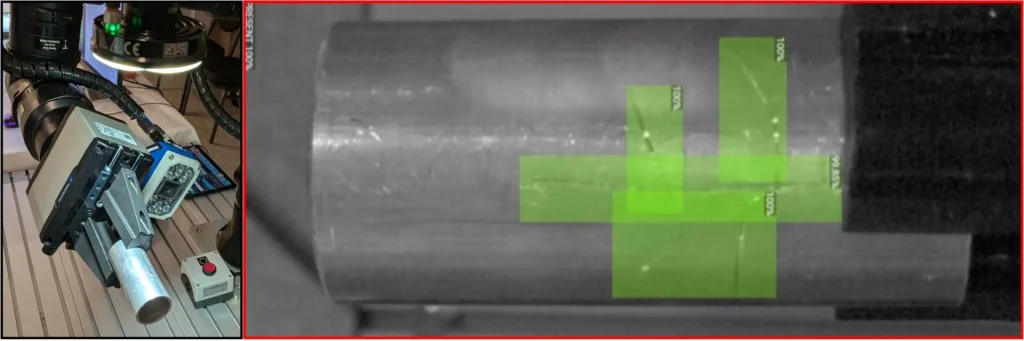

Modular Robot with a Smart Camera for 360° Surface Inspection

A collaborative robot arm equipped with a Datalogic P3x Smart Camera (running Impact software) was used to locate and pick up metal tubes. It then rotated each tube in front of a separate fixed Datalogic industrial camera with a ring light mounted on the demo table frame. The PEKAT VISION Detector module analyzed the entire surface for scratches.

The module was trained on a dataset of various surface defects and accurately identified scratches in real time. Based on the inspection result (OK / NG), the robot sorted the tubes into separate bins.

This demo showed how collaborative robots can assist in AI-based quality inspection, especially when multiple angles are required — a topic we’ve covered earlier. The combination of robotics and deep learning enables fully automated inspection workflows.

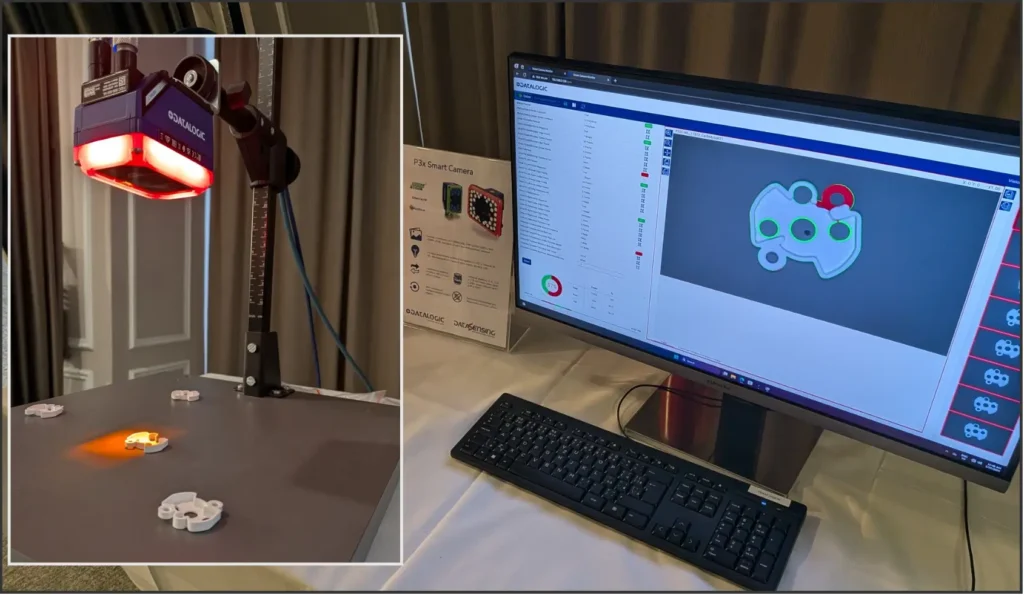

Inspection of Plastic Parts Using Impact and the P3x Smart Camera

In this demonstration, the P3x Smart Camera ran Datalogic’s IMPACT software to inspect small plastic parts using a combination of classic machine vision tools:

- Blue Eye Tool – for part localization in the image

- Circle Fit – to measure the diameter and detect deviations in holes

- Grayscale Template – to evaluate shape and identify defects

These tools illustrate the power of rule-based vision algorithms, which are still highly effective for structured inspection tasks. In a follow-up demo, we explored how these traditional tools can be enhanced by combining them with deep learning.

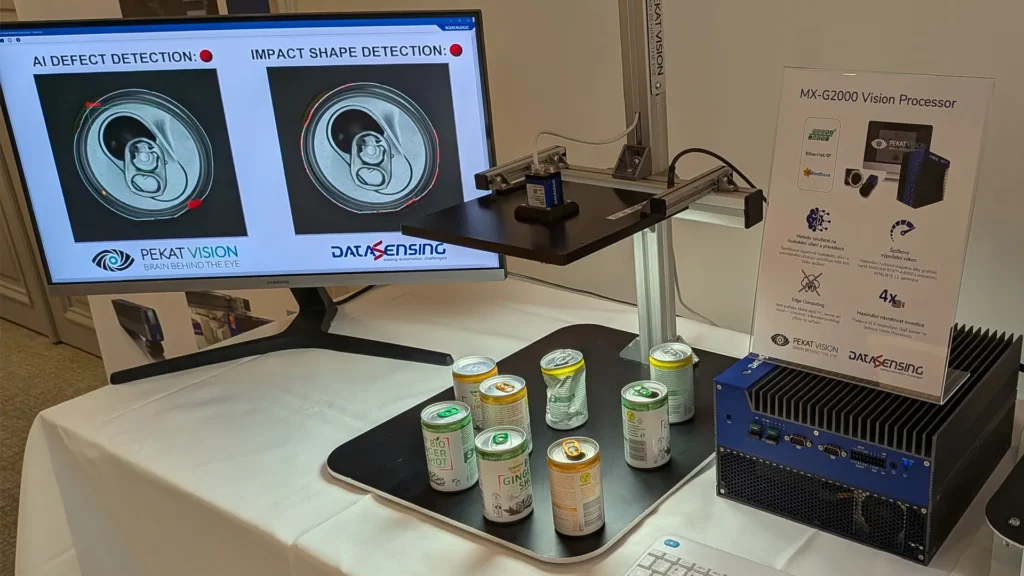

Surface Quality Inspection and Geometric Control

This hybrid demo demonstrated the fusion of rule-based vision and deep learning on small aluminum cans:

- Geometric measurements were handled by the Circle Fit tool in Impact.

- Surface defects like scratches were identified using PEKAT VISION Surface Detector.

- The state of the can (OK / Open / Missing Pin) was classified using the Detector module with three classes.

All evaluations were displayed side by side within a single application interface — PEKAT VISION running inside IMPACT, running on the MX-G2000 Vision Processor.

This powerful setup shows how combining AI and traditional vision creates a robust and scalable inspection system. You can learn more about the difference between rules-based and deep learning-based machine vision in our earlier article.

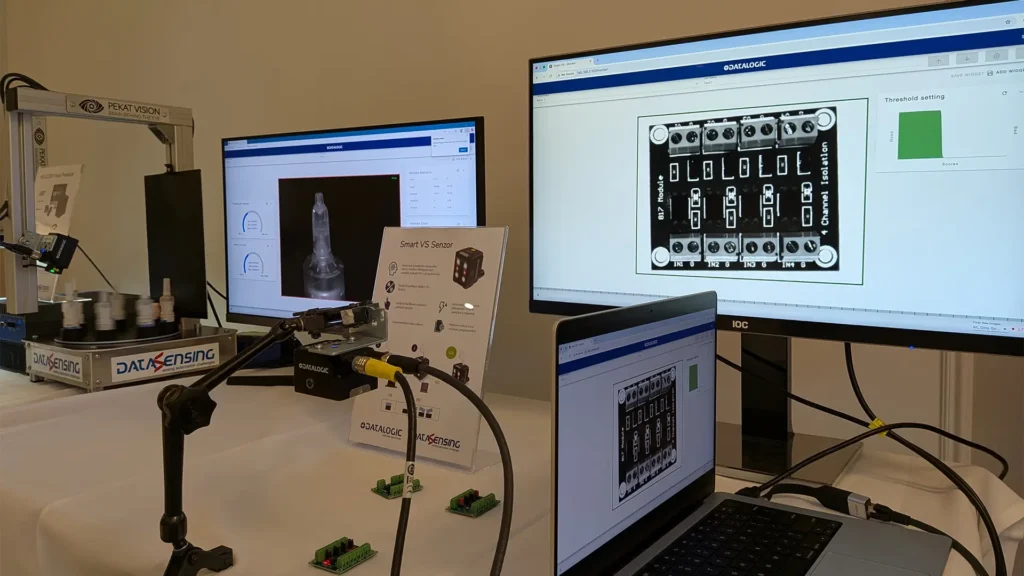

Simple Inspection with Smart Vision Sensor (Smart VS)

For a minimal hardware setup, we presented a simple demo using the Smart VS sensor — the most basic product in our vision sensor family.

The Smart VS inspected small plastic bottles on a rotating turntable, classifying each as either OK or NG (not good). Despite its simplicity, the NG class included multiple defect types such as:

- Missing cap

- Missing seal

- Misaligned or improperly screwed cap

Each inspection took under 50 milliseconds, proving that even compact systems can offer high-speed AI inspection with just two output classes.

Sneak Peek at What’s Coming Next

We also showcased two upcoming products we’re especially excited about — stay tuned for their official launch on our website!

Thank you to everyone who joined us at the workshop and to our partners who helped make it possible. If you’re interested in more details about any of the demos or technologies, don’t hesitate to contact us or try our interactive demo.