Explore our complete range of machine vision products developed by the Datalogic Group, covering both deep learning and traditional rule-based technologies. From compact smart sensors to high-performance vision processors and advanced inspection software, our portfolio enables reliable visual inspection, measurement, guidance, and identification across a wide range of industries and applications.

Deep Learning Vision Solutions

AI-Based Inspections for Visual Complexity or Simple Classification Tasks

Our deep learning portfolio is designed for visual inspection tasks where traditional rule-based systems often fall short — such as detecting unpredictable defects, recognizing irregular objects, inspecting surfaces with natural variations, or when a simple OK/NG classification is required. These tools require no programming for standard applications and are easy to train with real production images.

From entry-level smart sensor with built-in AI to the new Smart VS EVO powered by deep learning with anomaly detection and up to six-class classification.

Intuitive AI vision platform for training and deploying deep learning models tailored to your inspection tasks.

Industrial PC with pre-installed PEKAT VISION and optional IMPACT software, combining deep learning with rule-based logic in one platform.

These solutions are ideal for applications like surface inspection, anomaly detection, defect classification, and binary classification (smart sensors) — especially when inspection rules are hard to define manually.

Rule-Based Machine Vision Solutions

Reliable, High-Speed Inspection with Deterministic Algorithms

Our rule-based systems rely on proven image processing tools that deliver deterministic performance and precise results, even in high-speed or tightly constrained applications. Included products:

All-in-one vision systems with built-in lighting, autofocus, and onboard IMPACT software. Ideal for label checks, measurement, robot guidance, and code reading.

High-performance platforms that support multiple cameras and parallel vision tasks on complex production lines.

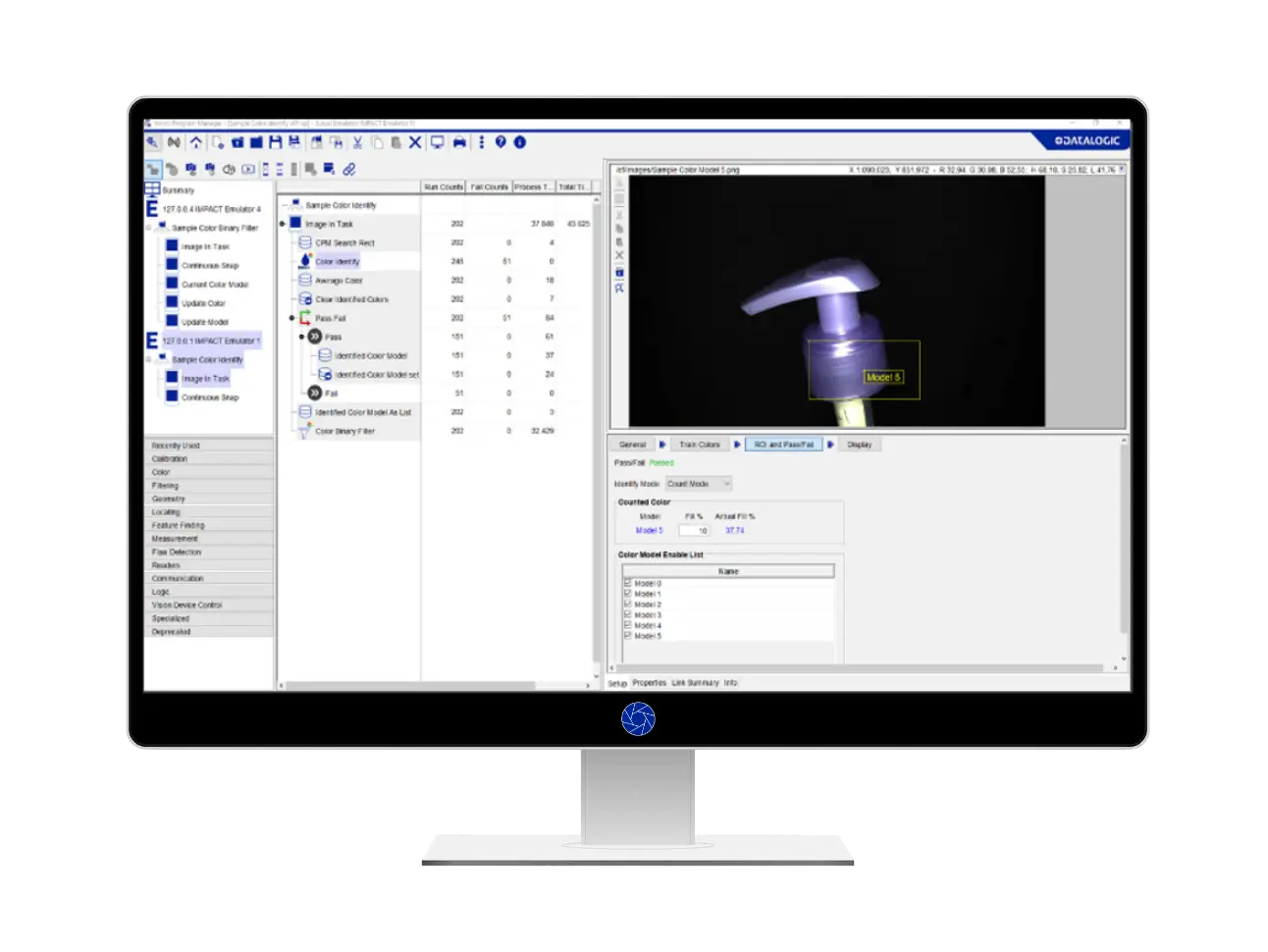

A comprehensive vision development environment offering over 100 tools for measurement, feature detection, code reading, alignment, and object verification — with sub-pixel accuracy and consistent real-time performance.

Rule-based vision is the preferred choice when your task involves precise measurements, stable patterns, or fixed object geometries that can be defined in advance.

Industrial Cameras

High-resolution cameras (up to 24 MP) for capturing detailed images in discrete part inspection.

Optimized for continuous surfaces or moving web inspection (e.g., film, packaging, textiles).

Comprehensive Solutions for Industrial Automation

Whether you need fast deployment, flexibility, or extreme precision, our machine vision solutions are built to scale — from entry-level quality checks to advanced automation tasks in complex production environments.

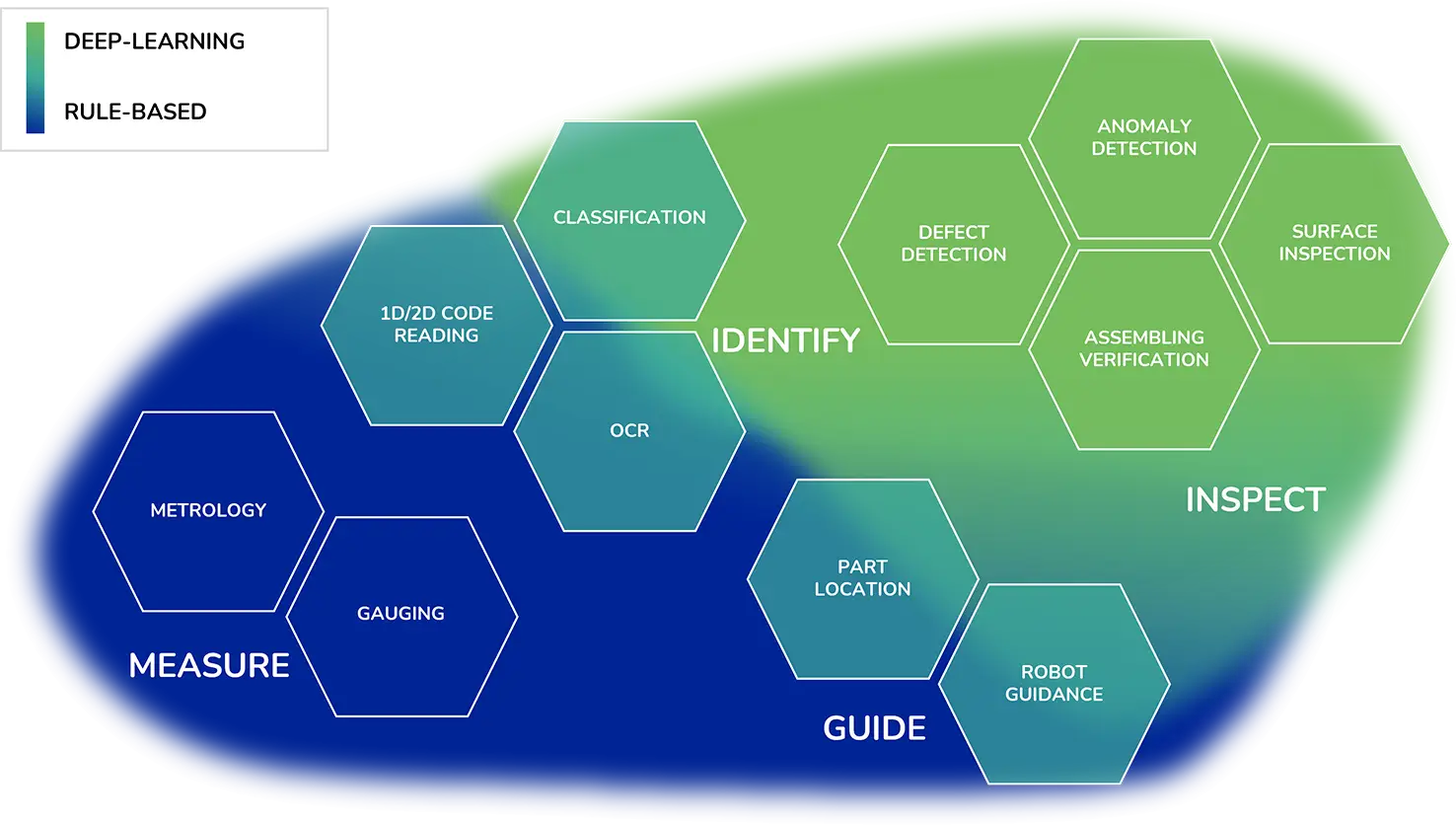

Choosing Between Deep Learning and Rule-Based Vision

Not sure which approach is the right fit for your application?

Below is a visual comparison highlighting the strengths of deep learning vs. rule-based machine vision across typical industrial tasks — such as defect detection, code reading, measurement, and robotic guidance.

For a deeper dive into how these technologies differ, see our blog post: Traditional vs. Deep Learning Machine Vision.

If you’re evaluating your options or have a specific challenge in mind, we’re here to help. Our team can assist you in selecting the most suitable solution for your needs — whether it’s deep learning, rule-based vision, or a hybrid approach.

Simply use the contact button below and let us know what you’re working on. We’ll be happy to advise.