In this use case, we show how PEKAT VISION AI software, combined with industrial machine vision hardware, enables reliable inspection of small aluminum cans for high-speed food and beverage production.

Ensuring that every aluminum can leaving the production line is mechanically intact and properly sealed is critical in this industry. Even minor defects — such as surface scratches, deformed lids, or missing pull-tabs — can compromise product quality, consumer safety, or brand perception.

Inspection Setup

The inspection system was designed to capture detailed images of the top side of each can, where the most critical features are located.

- Camera: Datalogic color area scan camera

- Illumination: Diffused ring light panel

- Imaging target: Top surface of aluminum cans

This setup ensured uniform illumination of highly reflective aluminum surfaces — a common challenge in can inspection — and is well suited for high-speed filling and processing lines where cans are consistently oriented, enabling reliable top-view inspection.

Two-Part Inspection Strategy

The inspection task was divided into two complementary parts to ensure that only complete and undamaged cans pass.

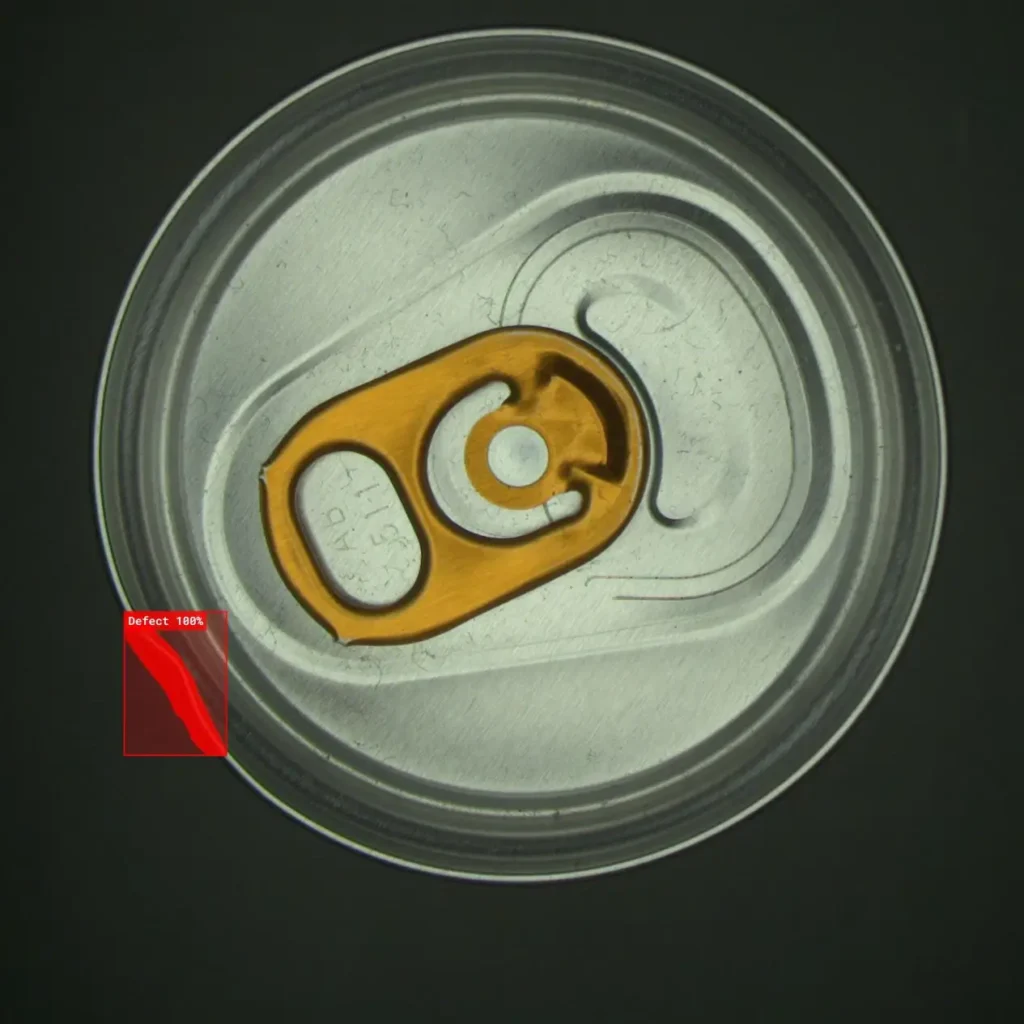

1. Surface and Shape Inspection

The first inspection focused on the physical condition of the can lid, using the Surface Detector AI module in PEKAT VISION.

The model was trained to identify:

- Cosmetic defects such as scratches on the top surface

- Geometric deformities of the top ring, including dents and out-of-round shapes

Although both defect types appear on the same area of the can, they represent fundamentally different quality risks. By using AI-based surface inspection, the system can reliably detect irregular, non-repeatable defects that are difficult to describe with fixed rules.

This approach is particularly effective for surface defects, where:

- Scratch patterns vary in shape and size

- Reflections change with lighting and material finish

- Rule-based algorithms struggle to generalize

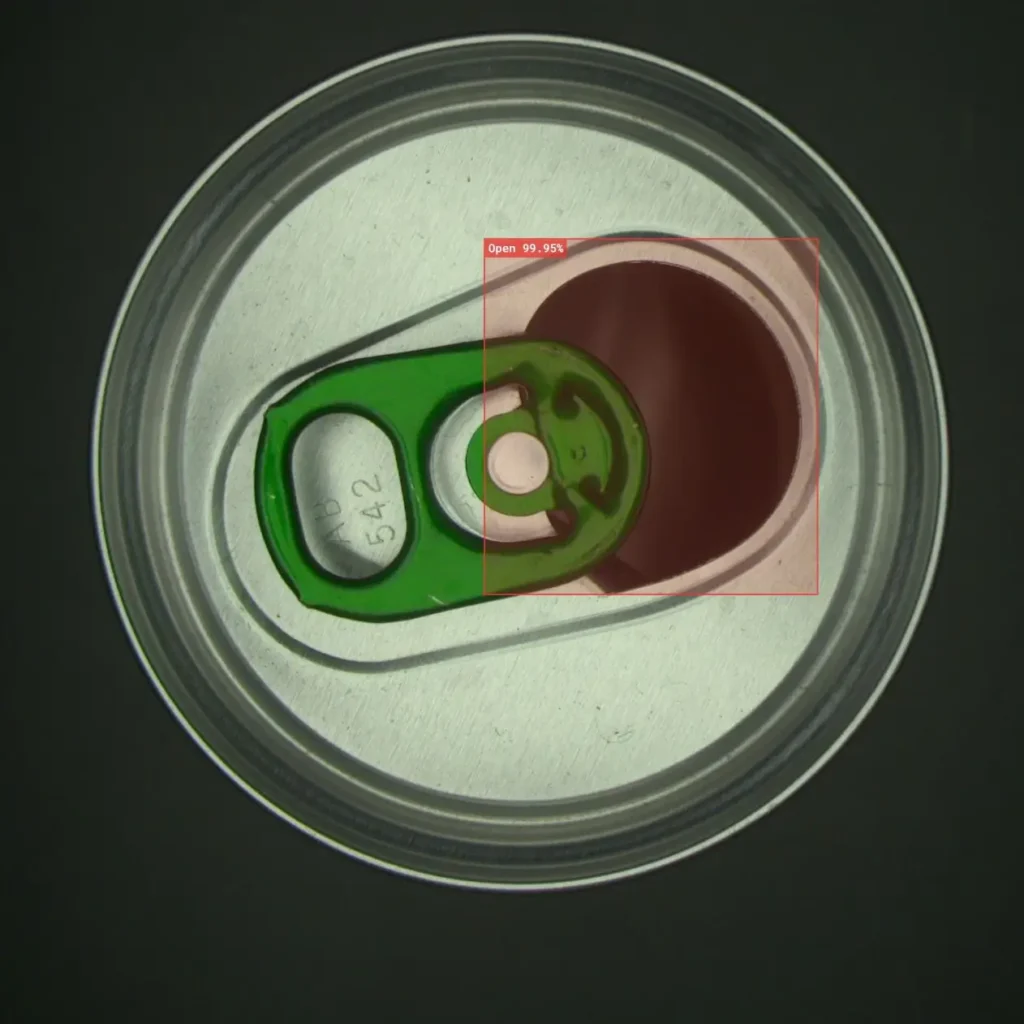

2. Pull-Tab and Open-State Detection

The second inspection verified the integrity of the pull-tab and whether the can was already open.

For this task, the Detector module was used with two trained classes:

- Open – the can has already been opened

- Missing – the pull-tab is not present

If either condition was detected, the can was immediately classified as NG (Not Good).

This step ensured that:

- No open cans passed inspection

- All cans had a correctly mounted pull-tab

Why AI Makes Sense — and When It Doesn’t

For inspecting surface scratches, AI-based inspection is clearly the most effective approach. The variability of cosmetic defects makes traditional, rule-based vision methods impractical.

However, for precise geometric measurements—such as detecting deviations in the circular shape of the top ring—an algorithmic approach can sometimes offer higher accuracy. For example, circle fitting methods, available in IMPACT software, can be used to measure exact geometries without requiring any image annotation.

On platforms such as the MX-G2000 Vision Processor, both approaches can run side by side:

- Algorithmic vision for precise geometric checks

- AI-based vision for complex, variable surface defects

This hybrid approach combines the strengths of both methods. A more detailed comparison of AI-based and algorithmic inspection methods is discussed in an earlier article, which we reference here for readers interested in deeper technical insight.

Addressing Food & Beverage Manufacturing Challenges

Aluminum can inspection presents several real-world challenges:

- High line speeds, requiring fast and reliable processing

- Highly reflective surfaces, demanding optimized lighting and camera settings

- Small defects, which must be detected consistently without false rejects

By combining optimized imaging, AI-based surface analysis, and targeted object detection, this inspection setup delivers robust performance even under demanding production conditions.

Reliable Inspection for Complete and Undamaged Cans

This two-part inspection approach ensures that:

- The can lid surface is free of unacceptable cosmetic or structural defects

- The pull-tab is present, and the can is properly sealed

As a result, only cans that are both complete and undamaged proceed further in the production process.

AI Vision Beyond This Use Case

While this example focuses on aluminum cans, the same inspection principles apply to many other food and beverage applications—such as contaminant detection, packaging inspection, cleanliness inspection, or quality check.

If you would like to evaluate a similar inspection on your own products, you can send us sample images or parts for a free feasibility study.