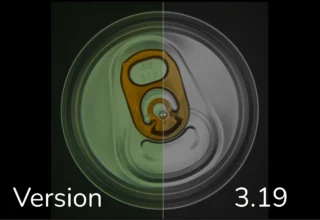

PEKAT VISION 3.19: More Flexibility, Better Control, and New Tools for Advanced Inspection

January 6th 2026

PEKAT VISION 3.19 brings improvements across communication, image handling, and usability — along with several powerful new modules designed to give users greater control over inspection logic, data handling, and customization.

Read more

EV Battery Inspection with AI

December 16th 2025

AI-powered inspection of EV battery components using depth maps to detect missing, incorrect, or misaligned parts with high accuracy.

Read more

Pill Counting and Quality Check with AI

August 25th 2025

Learn how PEKAT VISION uses deep learning for pill counting and quality checks, replacing scales and manual control with fast, reliable AI vision.

Read more

Introducing SMART VS EVO: AI Vision, Simplified

June 26th 2025

Introducing Smart-VS EVO — the latest evolution in smart sensing combining edge AI capabilities in one compact, easy-to-use device.

Read more

AI, Machine Vision and Industrial Automation

May 30th 2025

Explore highlights from our AI, Machine Vision, and Automation workshop — including robot-assisted quality inspection and combined AI and geometric analysis.

Read more

Automating PCB Inspection

April 16th 2025

Our example project demonstrates how multiple PEKAT VISION modules—Detector, Unifier, and Classifier—work together to inspect PCB components.

Read more

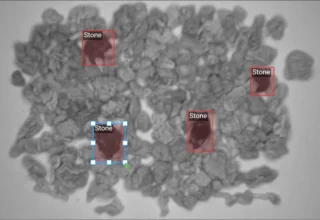

Detecting Food Contaminants with the Detector Module

April 3rd 2025

Take a closer look at how does the detector module work in food inspection. Now, you can try it yourself—or just read along.

Read more

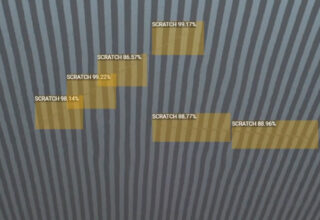

Defect Detection on Reflective Surfaces

February 21st 2025

Patterned illumination significantly enhances defect detection on glossy and reflective surfaces. Combined with PEKAT VISION's deep learning software, it provides a reliable, automated quality control solution for challenging inspection tasks.

Read more

PEKAT VISION RELEASE 3.18: What’s New?

January 17th 2025

The latest release of PEKAT VISION, version 3.18, brings exciting new features and improvements designed to enhance performance, usability, and flexibility for your quality inspection projects.

Read more

Ensuring Patient Safety with Reliable Catheter Packaging Inspection

January 9th 2025

Discover how PEKAT VISION detects incomplete or improperly sealed catheter packages to meet the highest quality standards.

Read moreGet In Touch

Do you need more information? Let us know, we will answer any question you may have.

PEKAT VISION is now part of Datalogic Group