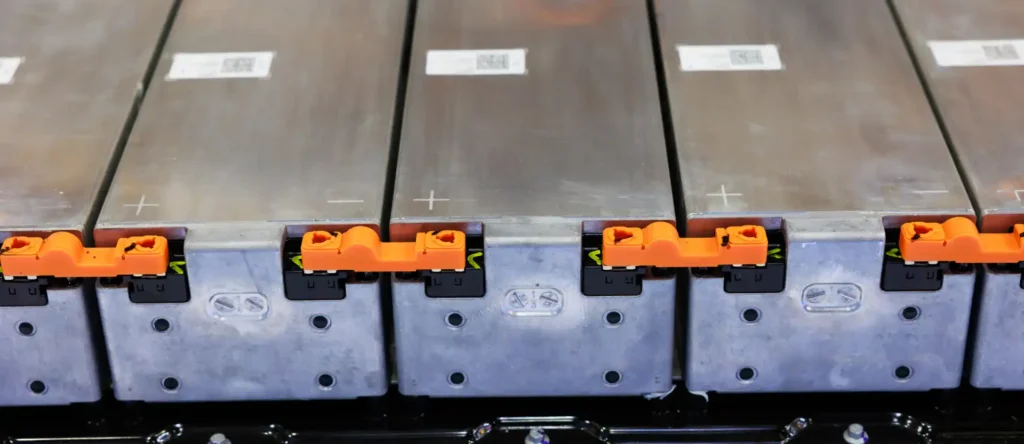

Ensuring that every component is present, correctly installed, and free of defects is essential in modern electric vehicle (EV) battery production. Even small assembly mistakes—such as a missing or incorrectly sized protective cap—can lead to costly rework or, in the worst case, safety risks.

To demonstrate how AI vision can support these challenges, we built an inspection workflow using three automotive batteries arranged in a row, simulating EV battery cells. Each unit required two protective caps. The caps used for the demonstration came in two height variants, allowing us to evaluate whether the correct type was applied.

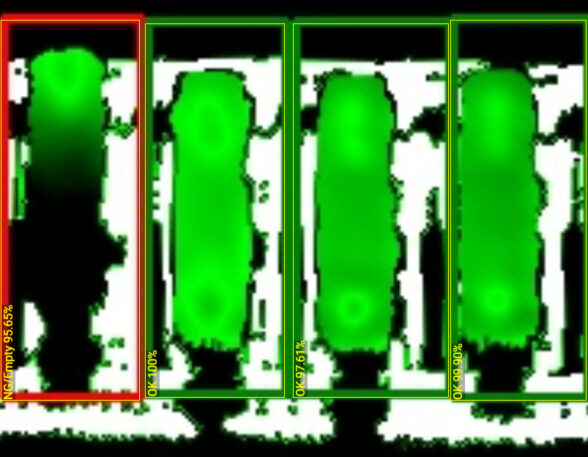

Battery Inspection with a depth map

With a standard 2D camera, the height difference between the caps could be difficult to spot. Instead, we used a 3D scanner to capture the complete surface profile and convert the data into depth maps, where height variations appear clearly:

- Lower areas appear brighter

- Higher areas appear darker

This made even subtle deviations easy to detect.

How PEKAT VISION Performs the Inspection

Since the batteries were always positioned consistently, PEKAT VISION’s Classifier module was ideal for the task. The software evaluated each depth map and identified four possible outcomes:

- Correct cap

- Incorrect cap (wrong height)

- Missing cap

- Missing battery

These conditions were instantly and reliably classified, with no sensitivity to slight variations in appearance or environmental conditions. The same approach scales well to EV battery lines, where hundreds of such elements must be checked in real time.

Enhancing EV Battery Quality with AI-Based Inspection

While this example demonstrates how PEKAT VISION can detect missing or incorrect components, the same AI workflow extends to many other EV battery manufacturing tasks.

During assembly, a single foreign object, misplaced component, or assembly variation can compromise performance or safety. PEKAT VISION’s deep learning modules — Detector, Classifier, Surface Detection, and Anomaly Detection — allow manufacturers to automate a wide range of checks, such as:

- Verifying correct assembly and component placement

- Detecting dents, scratches, or surface defects on battery housings

- Identifying foreign objects before sealing or packaging

- Checking correct orientation and presence of connectors, pads, or labels

Whether the source is a 2D industrial camera, 3D scanner, smart camera, or multi-camera system, PEKAT VISION delivers fast and reliable inspection throughout the production process.

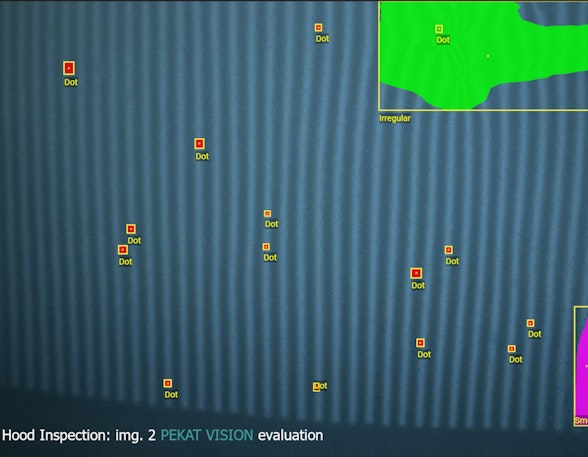

Explore Other Automotive Quality Inspection Cases

If you’re evaluating AI vision solutions for electric mobility or broader automotive manufacturing, these related applications may also be useful. They show how PEKAT VISION handles diverse quality challenges—from verifying car body components to checking fuse layouts—and demonstrate how the same software platform can support multiple inspection points across production.

- Car Body Panel Surface Inspection – Detecting subtle irregularities, dents, and defects

- Fuse Box Verification – Ensuring each fuse is the correct type and in the correct position

If you would like to evaluate whether PEKAT VISION is suitable for your application, feel free to send us your images or samples for a free feasibility study. We’ll be happy to assess the best inspection approach for your production needs.